Profile Specification

Profile Specification

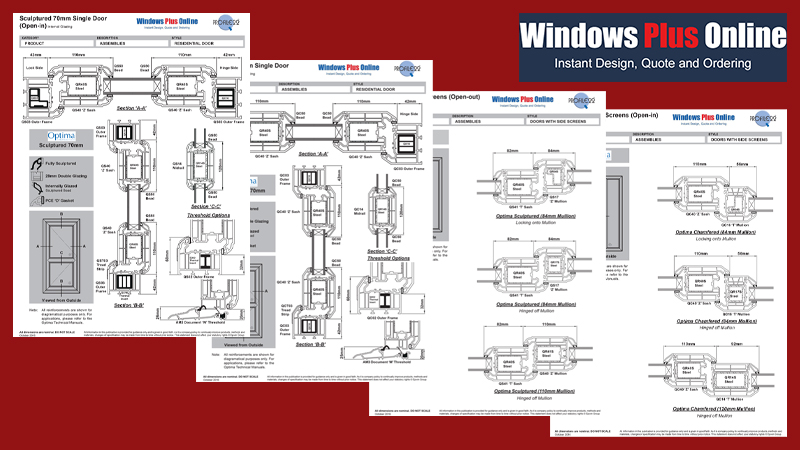

Windows Plus Online manufactures all uPVC doors from Profile 22 optima range.

uPVC

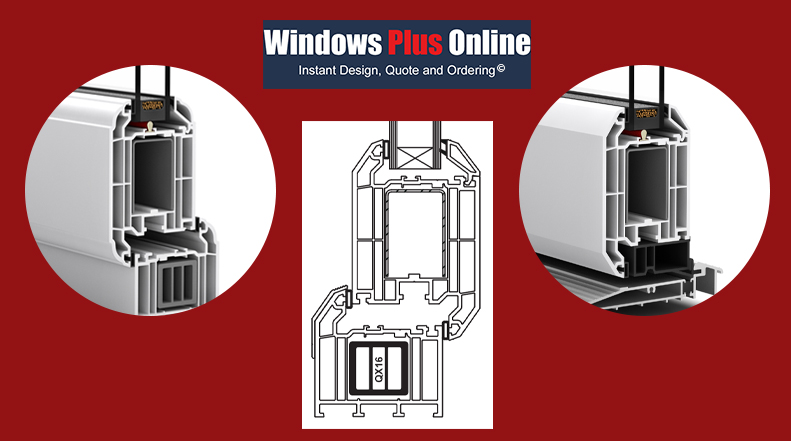

Profile 22 optima is a high-grade profile that is a fully-integrated full 70mm system, available in both chamfered and sculptured variations and is used nationally all over the UK.

A chamfered frame is a more traditional look and is the design used when uPVC doors were first developed. Sculptured uPVC doors were added around 2005 as a more modern look when the extrusion process evolved.

The profile 22 optima system meets all requirements for thermal efficiency as standard, and a wealth of intelligent design features have been added in the development of the profile. 6 thermal chambers as Windows Plus Online uses RCM as standard this increases the chambers 8 chambers which is market leading thermal efficiency and structural rigidity. There is also strategic, local wall thickening used to increase the two external faces durability and within the extruded components for better hardware retention and screw grip where required.

Panels

The door panels supplied from Windows Plus Online are manufactured using the latest technology and are formed using a vacuum process. Using the VEKA 151 panel there is no doubt the world renown recognised suppliers, and are by far the best on the market. The uPVC skins are pressed with 3.5 tons per SQM to a core of E.H.D.N polystyrene, and a central MDF reinforcement as standard. The process makes the panels resistant to heat and moisture, and the core materials are free from CFCs.

If you choose to have a coloured panel, this process is completed by using the latest machinery, making sure that this reduces the chances of damages to the panel and reducing the probability of foreign contaminations to next to zero. These bring a consistent application of the 2 pack system using an epoprime epoxy primer, which facilitates the use of dispersion glue. The foil is lined with a holt melt adhesive using a specifically designed application pad, increasing the quality to be second to none. The panels are then checked via an inspection machine for any distortions.

Arch door bending process and measuring

Windows Plus Online spent many years developing the non-template designer. Making ordering an arch door a simple task. You can measure the width and the height to the spring line (point where the arch starts) and the designer does the rest. There is also a guide on how to check quickly and easily if the arch is a true arch, the designer explains and allows you to move through the process quickly.

Arch door bending is a complex process. The profile to be bent is heated to 130deg C with nylon formers in place. The heating process makes the uPVC a pliable material and the formers keep the shape to the frame work. Once the profile and formers have the correct elasticity for bending the item is removed from the oven and is ready for the formers to be removed and the uPVC frameworks to be placed in the computer controlled bending jig. The correct arch is formed via a computer controlled CNC machine to form the perfect arch every time. The material is left to cool for a number of hours until completely set in position. Once set the arch is then inspected on a DTI inspection table. Currently 99% of all arches bent pass the inspection process first time. The arch is always bent over size then cut down to suit the square frame work and welder together. This is then inspected again on the DTI inspection table to ensure the spring line position is correct and is perfectly square. Windows Plus Online believes their arch quality is by far the best in the UK due to the amount of time the framework is inspected throughout the process.

Panels

The door panels supplied from Windows Plus Online are manufactured using the latest technology and are formed using a vacuum process. Using the VEKA 151 panel and Pilkington glass designs there is no doubt the combination of the two world renown recognised suppliers, and are by far the best on the market. The uPVC skins are pressed with 3.5 tons per SQM to a core of E.H.D.N polystyrene, and a central MDF reinforcement as standard.

The process makes the panels resistant to heat and moisture, and the core materials are free from CFCs. All glass designs are supplied with lead as standard and a speciality design glass colour bonding resin, again adding the quality and the best aesthetics to the product. If you choose to have a coloured panel, this process is completed by using the latest machinery, making sure that this reduces the chances of damages to the panel and reducing the probability of foreign contaminations to next to zero. These bring a consistent application of the 2 pack system using an epoprime epoxy primer, which facilitates the use of dispersion glue. The foil is lined with a holt melt adhesive using a specifically designed application pad, increasing the quality to be second to none. The panels are then checked via an inspection machine for any distortions.

Gaskets

With profile 22 optima gaskets are co-extruded as part of the extrusion process, meaning there is never shrinkage in turn improving the longevity of the arch door in heat efficiency and weather tightness.

Additional Links

Below you will find the technical documentation which relates to the uPVC gaskets.

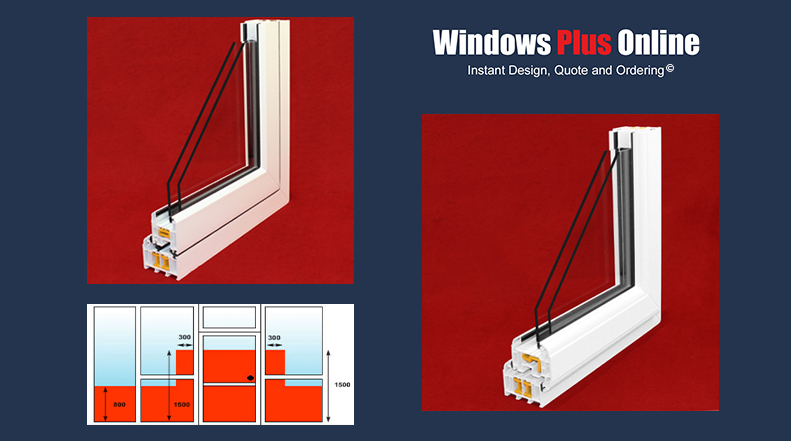

Midrails

An arch door has a selection of varied options. Windows Plus Online uses the design relative to the application. All doors with midrails are supplied with a medium size of 84mm unless a letterplate is selected, then this is automatically changed to 120mm to allow for the letterplate to be fitted. Sometimes due to the size restrictions on the side panels midrails have to be mechanically jointed into the outer frame, as opposed to welded.

Ancillaries

Profile 22 optima has an extensive range of frame packers (sometime referred to as knock-ons or add-ons), giving you confidence every configuration can be addressed. Bridging packers for the glass units are provided free of charge with all items manufactured at Windows Plus Online to make sure the glass has a free flow of air around the unit.

Internal Bead

All windows and doors from the profile 22 optima range are manufactured as standard to be internal glazed, adding security and ease of fitting. In addition to this the window have been security passed and are ready for proposed enhancements to PAS 24.

Additional Links

Below you will find the technical documentation which relates to the uPVC arch door profile.

Building Regulations and Certification

Profile 22 optima meets all requirements not only for UK and European building regulations, under instruction profile 22 optima can be manufactured to conform to Document Q approval, PAS 24 approved, Secured by Design solutions. All items are British Standards group approved, under ISO 9001 / ISO14001 / OHSAS18001, profile 22’s commitment to responsible sourcing BES6001 licence produces all this, put together reflects the commitment to quality and increases the supply chain’s open and honest approach.

For more information, please see the building regulations page.