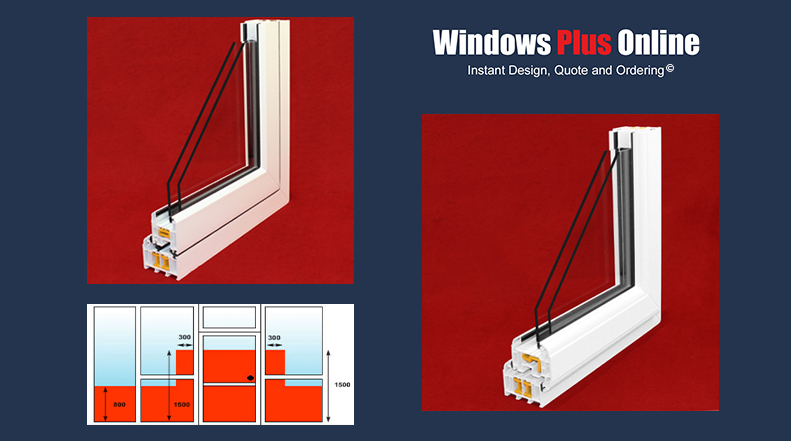

Profile Specification

Profile Specification

Windows Plus Online manufactures composite doors using Eurocell uPVC profile.

uPVC

Eurocell uPVC is a high-grade profile that is a fully-integrated 70mm system, chamfered, and is used nationally all over the UK for composite doors to give the door a more traditional look. The Eurocell system meets all requirements for thermal efficiency as standard, and a wealth of intelligent design features have been added in the development of the profile.

With 6 thermal chambers Windows Plus Online and the use of RCM as standard this increases the chambers to 8 chambers which is gives some of the highest thermal efficiency and structural rigidity in the market place. There is also strategic, local wall thickening used to increase the two external faces durability and within the extruded components for better hardware retention and screw grip where required.

Additional Links

Below you will find the technical documentation which relates to the Eurocell uPVC specification.

Slabs

Windows Plus Online use the Door-stop door slabs which are a household name throughout the UK. The slab is 44mm thick, GRP skinned, and come in a range of designs. To give great definition and long life performance Door-Stop slabs use glass reinforced plastic skins. For keeping people safe, secure and protected against all weather conditions. It's used today to make the hulls of boats because it's super-strong and has exceptional wind and water resistance. That's why we use it for our composite doors.

The average rainfall in the UK is between 700mm a year in East Anglia, and up to 3,000mm a year in the Scottish Highlands. To make sure Door-Stop slabs are up to this demanding task they are tested in a pressurised chamber to stimulate gusting winds starting at 63 miles an hour and up to 80 miles an hour. Then they are tested further by spraying two litres of water every minute directly at the door in their test chamber.

Wind resistance: tested in accordance with BSEN 12211: 2000

Air Permeability: tested in accordance with BSEN 1026: 2000

Water tightness: tested in accordance with BSEN 1027: 2000

Edging: The hinge edge of your door has a PVC edging. Then we cut through the edging so that the hinge sits neatly inside the edge of your door. To make the door super-strong, the lock edge has been fitted with a full length of 4mm thick, powder-coated aluminium lock strip. Then your preferred lock sits flush inside your door.

Additional Links

Below you will find the technical documentation which relates to the composite door slabs.

Door Cassettes

Door glazing is secured using colour and finish matched cassettes. These are secured using security glazing clips, and screwed together from internally increasing security. These are re-glazable to change glass design should you wish at anytime in the future.

Additional Links

Below you will find the technical documentation which relates to the composite door slabs.

Tolerances

The manufacturing tolerances for composite doors and/or side panels are compliant with the British Standard requirements of +/-3mm.

Colours

The door can be as individual as you like. Three new door colours; Poppy Red, Duck Egg Blue and Black Brown, have added to our existing ten; White, Black, Blue, Red, Green, Oak, Darkwood, Cream, Grey and Chartwell Green.

We also offer colour all-round options, and 9 frame colours - white, mahogany, cherrywood, oak, white grain, brown-black, grey, cream and Chartwell green - to compliment your new door colour. All of which can be configured with gold, chrome, black, white and contemporary hardware; it's easy to see how there are over 5 million types of your door designs.

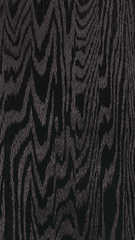

Black Brown

Black Brown

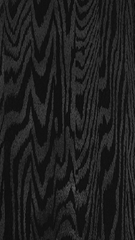

Black

Black

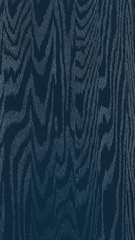

Blue

Blue

Chartwell Green

Chartwell Green

Cream

Cream

Dark Wood

Dark Wood

Duck Egg Blue

Duck Egg Blue

Green

Green

Grey

Grey

Light Oak

Light Oak

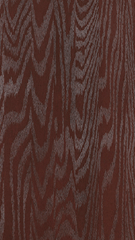

Poppy Red

Poppy Red

Red

Red

White

White

Building Regulations and Certification

Eurocell meets all requirements not only for UK and European building regulations, under instruction Eurocell can be manufactured to conform to Document Q approval, PAS 24 approved, Secured by Design solutions. All items are British Standards group approved, under ISO 9001 / ISO14001 / OHSAS18001, Eurocell commitment to responsible sourcing BES6001 licence produces all this, put together reflects the commitment to quality and increases the supply chain's open and honest approach.

For more information, please see the building regulations page.

Composite Side Panels

Composite door panels used in side panels are made in the same way that the slab is made, and are installed into the frames as you would glass. These are 28mm overall in width, and the glazing is the same as the composite door glazing. The colours and colouring process is the same as the slabs.

Additional Links

Below you will find the technical documentation which relates to the composite side panels specification.